Mango fruits are usually eaten fresh as dessert or as relish depending on their stage of maturity when picked. Most mango growers have not put the technology into practice due to the high cost of additional farm inputs necessary for its successful implementation during the rainy season. Mangoes are processed at two stages of maturity. Green fruit is used to make chutney, pickles, curries and dehydrated products. The green fruit should be freshly picked from the tree. Fruit that is bruised, damaged, or that has prematurely fallen to the ground should not be used. Ripe mangoes are processed as canned and frozen slices, purée, juices, nectar and various dried products. Mangoes are processed into many other products for home use. Some of the products are given below.

MANGO PROCESSING -PROCESSED PRODUCTS

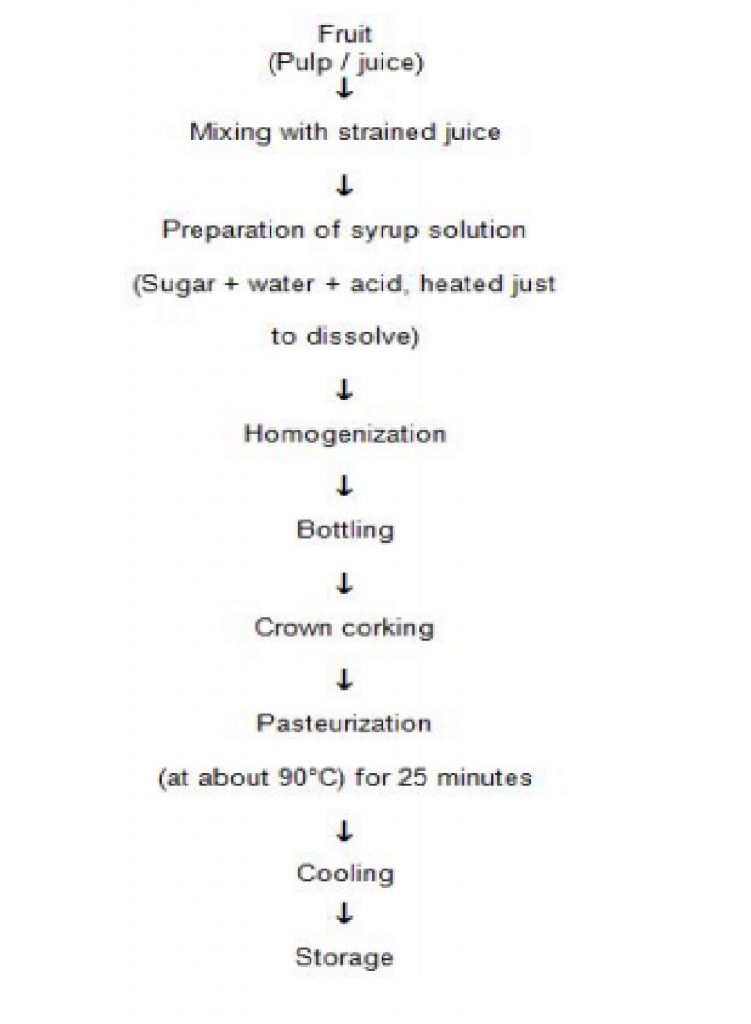

1. MANGO SQUASH

2. MANGO RTS

3. MANGO JAM

Ingredients

Mango pulp – 1 kg

Sugar – 750 g

Citric acid – 20 g

Method

• Mix the mango pulp and sugar thoroughly in a clean stainless-steel vessel

• Add citric acid and boil the mango pulp and sugar till jam consistency (68°bx) is reached.

• Fill hot in sterilized bottles, cool and store .

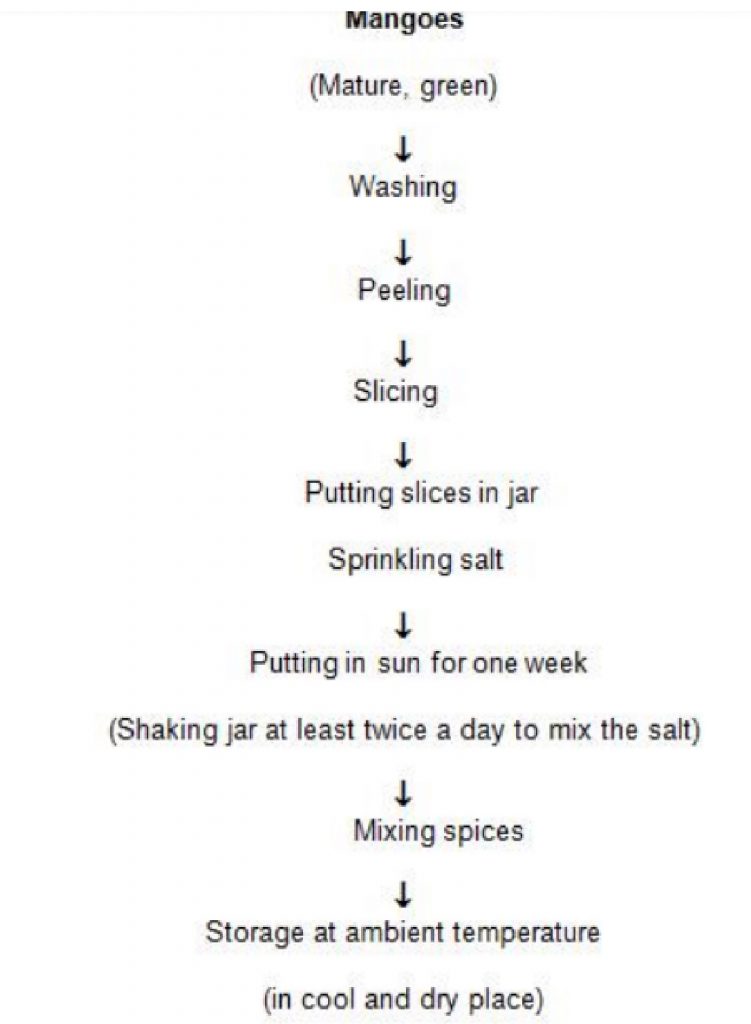

4. MANGO PICKLE

Ingredients

• Mango (peeled and sliced) -1 kg,

• salt – 200 g, red chili powder 10 g, asafoetida -5 g, fenugreek, black pepper, cardamom (large), cumin and cinnamon (powdered) each 10 g, clove (headless) 6 numbers.

5. IMMATURE MANGO (MAVADU)

Ingredients

Raw mango small sour variety 100

Salt 2 kg

Fenugreek 350g

Redchillies 700g

Turmeric 125g

Castor oil 100ml

Mustard oil 500ml

Method

• Wash and wipe mangoes.

• Apply castor oil to the mangoes.

• Mix with salt and keep aside.

• Roast and powder fenugreek seeds and mustard.

• Remove seeds from chilies, sun dry and powder.

• Peel garlic and grind along with all the other spices using salt solution drained from mangoes.

• Mix with sesame oil and stuff mangoes.

• Store in jars and pour remaining oil.

• Cover well, keep aside for 2 weeks before use.

6. SWEET MANGO CHUTNEY

Recipe

• Mango slices (or) shreds – 1.0 kg.

. sugar (or) gur – 1.0 kg.

• salt – 45 g.

• onions (chopped) – 50 g.

• garlic (chopped)-15 g.

• ginger (chopped) – 15 g.

• red chilli powder – 10 g.

• black pepper, cardamom, cinnamon, cumin – 10 g each.

• cloves – 5 nos.

• vinegar – 170 ml.

6. MANGO CANDY

Ingredients

Mango 1kg

Sugar 1.20kg

Water 500ml

Citric acid 6.4g

KMS 1.2g

Method

• Selection of ripe mango fruit

• Cutting into pieces

• Soaking in 2% CaCl2 solution

• Preparation of sugar syrup (Addition of sugar, water, citric acid)

• Cooking the fruit in sugar syrup till soft consistency (TSS 750 brix and temp. 106 ℃)

• Soaking the fruit for 7 days

• Boiling of sugar syrup to 60 0 Brix

• Packing the mango preserve in glass jar

• Draining the sugar syrup

• Drying in shade to get mango candy

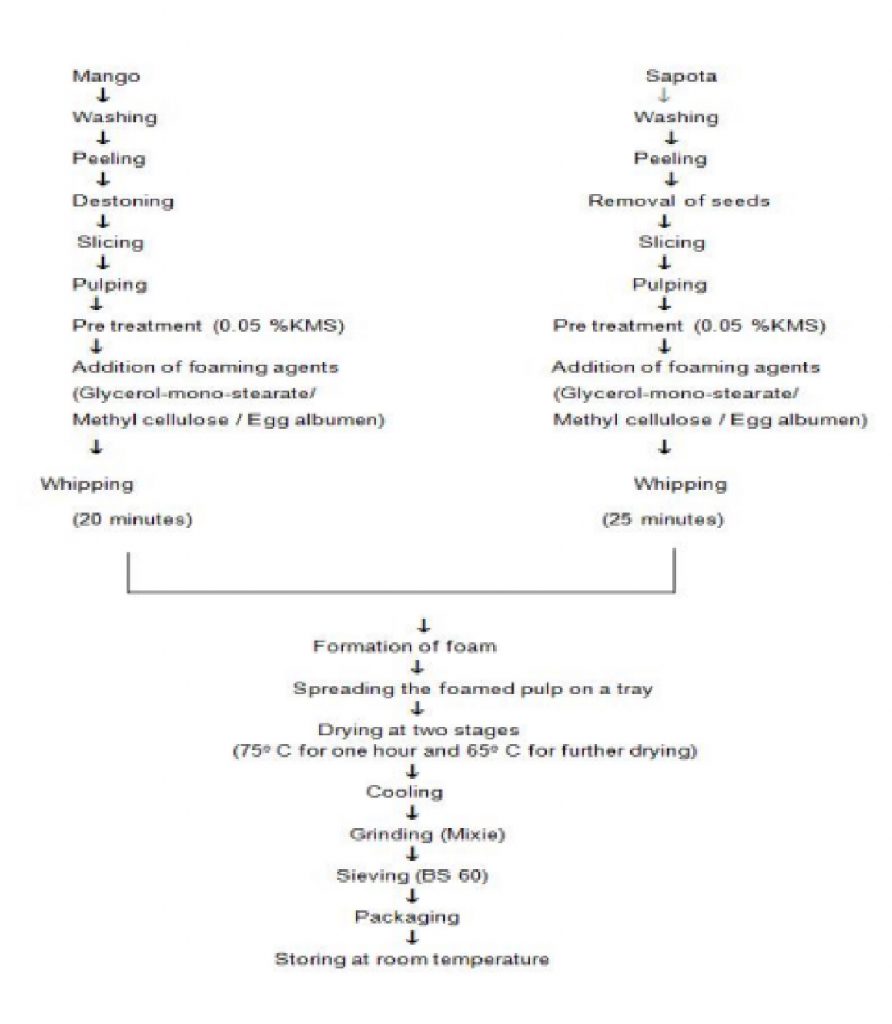

DEHYDRATED MANGO PRODUCTS

1. Dried mango

Dehydrated or dried mango slices are among the first products manufactured commercially from ripe mango fruits that caught the attention of consumers in the international market for processed tropical fruits.

Preparation of dried mango

- The fruit is washed thoroughly. The cheeks are sliced with a sharp stainlesssteel knife. Each slice is then cut into two or three pieces lengthwise. The flesh is scooped from the skin with a stainless-steel scoop or ladle.

- Sugar syrup is prepared by adding 175 kg sugar, 1.7 kg citric acid and 0.85 kg sodium metabisulfite in 175 l H2O to make a 45 Brix sugar concentration and heating to 90°C to dissolve the metabisulfite.

- The prepared mango slices (1 t) are added to the syrup.

- The preparation is heated to 90°C and then allowed to stand for at least 6 h. Subsequently, the sugar concentration of the syrup is adjusted by dissolving more sugar until the concentration reaches 50 Brix using a hand refractometer.

- After 6 h, the mango pieces are again removed from the syrup and the sugar concentration is adjusted to 60 Brix using a hand refractometer for the ‘plumping’ stage.

- The syrup is reheated to 90°C; the mango slices are added to the syrup and soaked for a further 6 h.

- The final step in the process involves the removal of mango pieces from the syrup.

- They are lightly rinsed with H2O to remove the excess sugar that may crystallize on the surface of the mango during drying.

- The slices are then loaded in drying trays and dehydrated at 40–50°C in a convection dryer. Drying time usually requires 18 h.

- The dried mango pieces are unloaded from the dryer and reconditioned at room temperature overnight. Each piece is coated with confectioner’s sugar. The product is then packed in aluminium-foil-laminated pouches and sealed.

2. Mango fruit bar

The product is also commonly referred to as mango ‘leather’. Purée processed from ripe mango is the preferred raw material for the manufacture of mango fruit bar. The prepared purée is heated for 2 min at 80°C with constant stirring to avoid scorching. The hot mixture is carefully transferred to stainless-steel drying trays. The trays are loaded into the dryer and dried for 14 h at 55°C. At the end of the drying operation, the dried sheets of mango should be pliable and should not stick to the fingers when touched.

The sheets of mango are removed from the trays. Six layers of the dried mango leather are stacked on top of each other. The edges are trimmed and bars measuring 2 × 4 cm are cut from the stack. Each bar is coated with confectioner’s sugar, wrapped in cellophane then packed in labelled plastic bags.

3. Mango fruit roll

The product and process are similar to mango fruit bar, and they only differ in the presentation. The total solids content of 1 t of mango purée is adjusted to 25 Brix using a hand refractometer by adding sugar to the purée. The amount of sugar needed depends on the initial total solids content of the mango purée. Then 2 kg each of citric acid and sodium metabisulfite are blended into the purée. The prepared purée is then heated for 2 min at 80°C with constant stirring to avoid scorching. The hot mixture is carefully transferred to stainless steel drying trays. The trays are loaded into a convection dryer and dried for 12–16 h at 55°C.

The dried sheets of mango are removed from the trays. Confectioner’s sugar is sprinkled over a stainless-steel-topped table to avoid sticking of the sheets on subsequent rolling. Each sheet is rolled manually into 1 cm diameter pieces. The ends are trimmed; and each roll is sliced into 5 cm long pieces. The pieces are coated with confectioner’s sugar and wrapped with cellophane. The rolls are then packed in appropriate containers.

4. Vacuum-puffed mango pieces

The ripe mangoes are washed thoroughly in chlorinated H2O, then sliced either mechanically or with a stainless-steel knife. The fl esh is scooped from the skin with a sharp stainless-steel ladle. The fruit pieces are then heated to 90°C in 30 Brix syrup containing 1% sodium metabisulfite, and steeped in the syrup for 4–6 h. The mango slices are removed from the syrup, rinsed briefl y in H2O, arranged in stainless-steel trays and loaded into the vacuum oven.

The mango pieces thus prepared are initially heated at a positive pressure of 40–50 kPa until the maximum tissue temperature of 100°C is reached, usually within 8 min. The pressure is released and the hot mango pieces are dried at −70 to −80 kPa vacuum at a temperature of 45–50°C. Total dehydration time under vacuum is 6 h. The above pressure temperature combinations provide the most desirable puff and rehydration characteristics.

5. Spray-dried Mango Powders

Spray-drying is by far the most cost-effective method for transforming fruit pulps into powder. Fruit pulp is very heat-sensitive and requires special treatments to produce competitively priced powders of superior quality.

6. Spray-dried instant green mango shake

Green mango shake on cracked ice is a very popular thirst quencher in Southeast Asia and elsewhere (Plate 85b). Its origin can be traced back to the countryside where finely sliced fresh green mango pieces are mixed with H2O, sugar and ice to make a cheap, wholesome summer drink during the mango season. When the green mango purée is spray-dried, a free-flowing white to greenish-white powder is produced that will dissolve instantly even in cold H2O. The powdering process offers unprecedented convenience to the consumer, especially when the powder is packed in sachets. Since no artificial or synthetic colours and flavouring agents are included in the liquid-feed formulation, the natural taste and aroma of green mango is retained in the powder.